Welcome to the website of TMTECK INSTRUMENT CO., LTD.

![]() info@tmteck-ndt.com

info@tmteck-ndt.com ![]() 010-89444420

010-89444420

Welcome to the website of TMTECK INSTRUMENT CO., LTD.

![]() info@tmteck-ndt.com

info@tmteck-ndt.com ![]() 010-89444420

010-89444420

Location: Home > Products > Hardness tester > Leeb hardness

THL280plus is an innovative improvement in hardness measurement mechanism and circuit performance. Low power design, connect computer, data exchange, mass storage (600 groups). No less than 100 hours of standby time, AA No. 5 ordinary battery power supply, easy to carry, more flexible replacement. It is especially suitable for work site and field operation, and for the needs of users at home and abroad.

Features

LCD display of 128×64 matrix with back-light, showing all functions and parameters.

Converts to all common hardness scales (HV,HB,HRC,HRB,HRA,HS).

English displaying and easy and convenient menu operation.

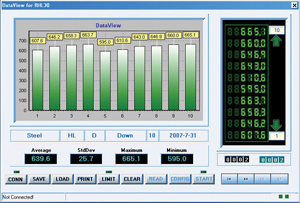

Powerful PC Software available and USB 2.0 interface & with the USB Protective Membrane.

7 types of Impact Device optional, which don't need to be recalibrated when changing them.

Memory of 600 groups data(impact times:32~1).Lower limit setting and sound alarm.

Material of “cast steel” is added; HB values can be read out directly when D/DC impact device is used to measure “cast steel” work piece.

Printer be separated from main unit and copies of testing results can be printed as required.

AA battery can easy change and transport.

Inbuilt function of Software Calibration.

Standard according including : national standard: GB/T 17394.1-2014; GB/T1172-1999

EU standard: EN ISO 16859-2016

ASTM standard:ASTM A956(2012)

Datapro for Hardness tester THL280 PLUS

Specifications

|

Hardness scale |

HL, HB, HRB, HRC, HRA, HV, HS |

|

Memory |

48~600 groups (impact times: 32~1) |

|

Measuring range |

HLD(170~960)See below table 1 and table 2 |

|

Accuracy |

±4HLD (760±30HLD) error of displayed value |

|

|

4HLD (760±30HLD) repeatability of displayed value |

|

Standard Impact Device |

D |

|

Optional Impact Devices |

DC/D+15/G/C/DL |

|

Max. Workpiece Hardness |

996HV(For Impact Devices D/DC/DL/D+15/C) |

|

|

646HB(For Impact Device G) |

|

Min. Radius of Workpiece |

Rmin = 50mm (with special support ring Rmin= 10mm) |

|

Min. Workpiece weight |

2~5kg on stable support |

|

Min. Workpiece thickness |

5mm (Impact Devices D/DC/DL/D+15) |

|

|

1mm (Impact Device C) |

|

|

10mm (Impact Device G) |

|

Min. thickness of hardened surface |

0.8mm |

|

Power |

AA battery |

|

Continuous Working time |

approx. 100 h (no back light off) |

|

Charging time |

2-3.5 h |

|

Operating temperature |

0~40℃ |

|

Relative humidity |

≤90% |

|

Overall dimensions |

125*67*31mm (main unit) |

Standard Configuration

|

Seq |

Name |

Qty |

Remark |

|

|

|

|

|

|

1 |

Main Unit |

1 |

Standard configuration |

|

2 |

Impact Device Type D |

1 |

Standard configuration |

|

3 |

Test Block Type D |

1 |

Standard configuration |

|

4 |

Cleaning Brush |

1 |

Standard configuration |

|

5 |

Supporting Ring |

1 |

Standard configuration |

|

6 |

Communication Cable |

1 |

Standard configuration |

|

7 |

Manual |

1 |

Standard configuration |

|

8 |

Carrying Case |

1 |

Standard configuration |

|

9 |

DataPro Software(USB) |

1 |

Standard configuration |

|

10 |

Battery Case Tool |

1 |

Standard configuration |

|

11 |

Mini-printer |

1 |

Optional configuration |